Construction Instructions for Water-Based Stadium Coatings

Key points of construction technology

Construction base surface requirements: The foundation is the soul of the entire site. The quality of a site depends to a large extent on the quality of the foundation project. It can be said that the foundation determines everything! A good foundation is the beginning of success, based on the characteristics of the surface coating and considering the service life of the site. If the base surface adopts cement concrete foundation, it should meet the following requirements:

(1) The newly poured concrete should have sufficient curing time (not less than 28 days).

(2) The surface flatness is good, and the allowable error of a 3-meter ruler is 3mm.

(3) The construction shall be carried out according to the design label to ensure that the stadium foundation has sufficient strength and compactness, and no cracks, delamination, powdering and other phenomena.

(4) Open drainage ditches are set around. In order to ensure smooth drainage, the base surface should have a slope of 5% and meet the design requirements.

(5) Temperature expansion joints should be reserved, generally 6m in length and width, 4mm in width, and 3cm in depth to prevent concrete cracking caused by thermal expansion and contraction. (7) Indoor venues should maintain good convection ventilation.

Base surface treatment

(1) Comprehensively check whether the construction surface meets the construction requirements, and preliminarily draw the marking position of the stadium temperature joint.

(2) Use a cutting machine to cut the temperature seam along the marking line, so that it is horizontal and vertical, so that the temperature seam is in a "V" shape.

(3) Wet the base surface with water, splash and wash the base surface with about 8% dilute hydrochloric acid, and then rinse it with clean water. Observe the remaining water traces, check the flatness and slope of the base surface, and mark the accumulated water with a marker pen. After cleaning and drying, the base surface should be free of white powder and floating dust.

(4) Filling with caulk. During construction, the water-based silicone PU ball joint adhesive material can be directly poured into the concrete expansion joints. Before filling the joints, the concrete expansion joints should be cleaned and a two-component sealing bottom should be applied.

paint. If the seam is deeper or wider, cotton sliver or rubber particles can be used as a bottom first, and then filled.

(5) After the base layer is dry, polish the obvious protruding parts, and repair the special concave parts with caulking material and anti-cracking leveling paint. For the insufficient density of the base layer, pour into the plastic substrate for reinforcement. Finally, it is recommended to stick a non-woven fabric with a width of about 50mm on the surface of the temperature seam.

Apply primer

(1) Construction of acrylic primer: According to the standard ratio, mix the primer with a certain amount of coarse quartz sand, water and a small amount of cement, stir evenly with a mixer, and scrape it twice to make the ground meet the flatness requirements of the tennis court. The special material is filled on the ground, and the thickness of each filling should not be too thick; construction of water-based silicone PU primer: mix A and B components evenly in proportion, and cure for 5 minutes before construction. This material is only suitable for concrete foundations During construction, the cement base surface should be firm, dry, clean, smooth, and free of oil stains and chalking. The recoating time of acrylic primer and mortar is about 4 hours, and the recoating time of silicone PU two-component primer is about 24 hours.

(2) Repair of accumulated water: the place where the depth of the accumulated water is not more than 5mm should be diluted with acrylic cement mortar and adjusted to a suitable construction consistency, and then applied to the accumulated water with a ruler or a scraper. Buffer layer construction can be carried out at the rear.

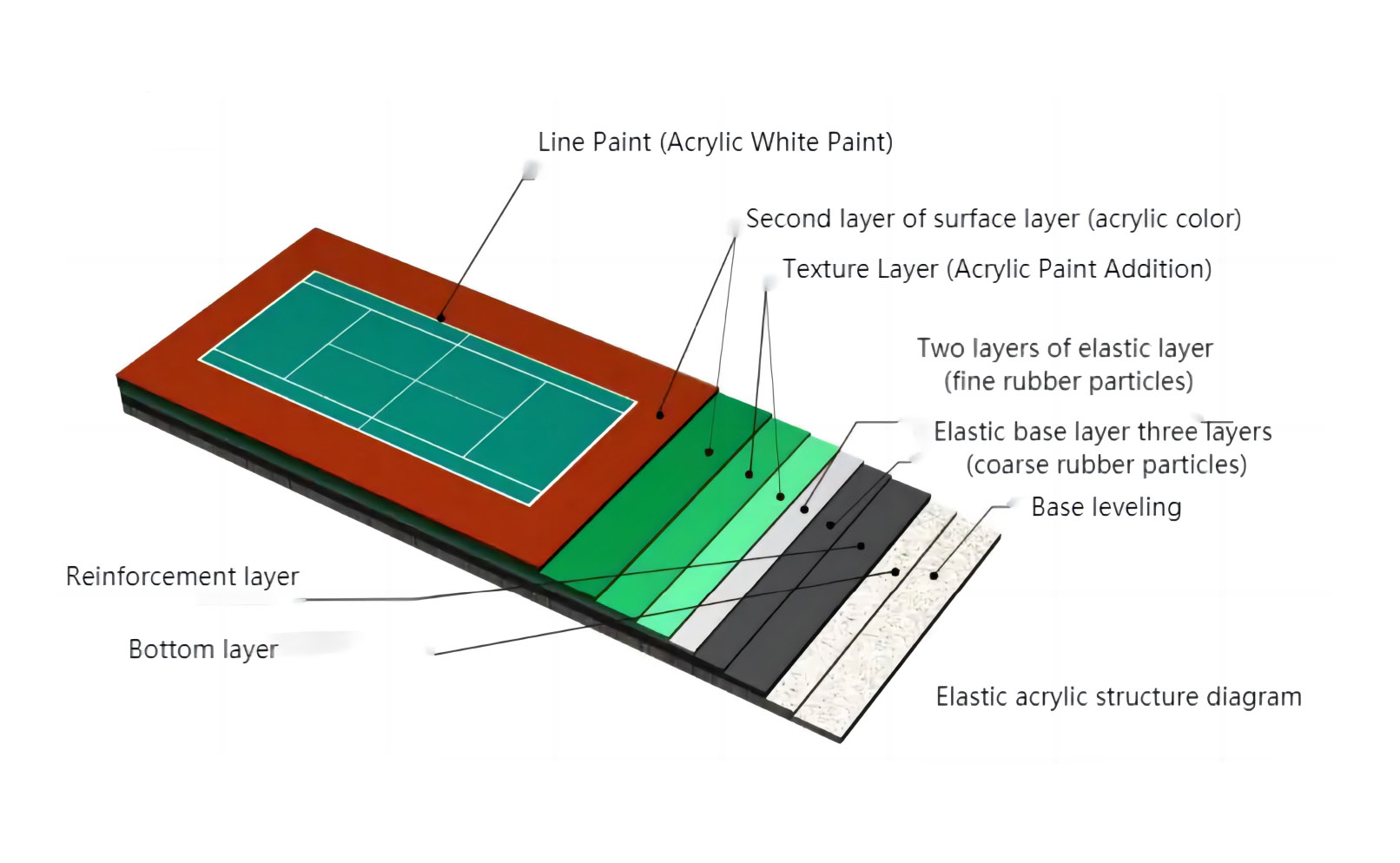

Construction of buffer layer (elastic layer)

(1) During the construction of the acrylic buffer layer, the topcoat is mixed with the quartz sand and smeared in two layers. Add quartz sand and mix to make the surface layer have a uniform texture effect, which can increase the wear resistance of the color coating and adjust the ball speed, so that the court meets the standard of use, that is, the surface of the court is rough. The texture layer should be scraped in the direction perpendicular to the bottom line of the dry court; the water-based silicone PU coating should be scraped directly, and 2-5% (mass ratio) of clean water can be added during construction, and electric stirring is used.

The machine can be used after stirring evenly (about 3 minutes), and the materials that have been added with water must be used up within 1 hour.

2) The construction of silicon PU adopts the method of thin coating and multi-layer construction, which can not only ensure the quality but also save materials. During construction, use a toothed scraper to scrape the buffer layer to dry the base surface. The thickness of each coating should not exceed 1mm. The time interval for each coating should be the drying time of the previous coating (generally about 2 hours), depending on the weather conditions on site. It depends, until the required thickness is reached (generally 4 coats). Pay attention to the leveling effect when applying and scraping. After the buffer layer is dry and solid, the surface flatness is tested by the water accumulation method. The water accumulation area is repaired and smoothed with the buffer layer. The surface where the granular debris is mixed or accumulated needs to be polished and smoothed by a mill before the next process construction.

Construction of topcoat layer

The acrylic topcoat is a one-component, and it can be applied by adding an appropriate amount of water and mixing it evenly. Generally, two coats are applied; the silicon PU court topcoat is a two-component material, which has excellent adhesion, excellent wear resistance and aging resistance, and has a long-lasting gloss. Keep it bright. It is composed of A component paint and B component curing agent, and the ratio is A (color paint); B (curing agent) = 25:1 (weight ratio). After the material is fully mixed, the surface layer is applied with a roller.

dash

(1) Lines can be drawn after the topcoat layer is cured. This material is a one-component material, shake well before use.

(2) During construction, mark the position of the boundary line according to the specifications and dimensions of the stadium, stick it along both sides of the boundary line with masking paper, use a small oil sweep to directly construct, and apply one to two strokes on the part of the stadium surface to be marked. Line paint, and peel off the textured paper after the surface is dry.

Precautions

1)Please check the local weather forecast before construction and make a complete construction plan;

2)Before using this product, it is necessary to do a basic moisture content test and a small experiment of material ratio. The basic moisture content is less than 8%, and the material ratio experiment is normal before large-scale construction can be carried out.

3)Please deploy at the construction site in strict accordance with the ratio of different materials stipulated by our company (weight ratio instead of volume ratio), otherwise the quality problems caused by the construction personnel have nothing to do with our company

4)Please store the material in a cool and ventilated place at 5℃-35℃. The storage validity period of unopened materials is 12 months. The opened materials should be used up at one time. The storage time and quality of the opened materials are not guaranteed.

5)Because the cross-linking curing is affected by air humidity and temperature, please construct when the ground temperature is between 10°C and 35°C and the air humidity is less than 80% to ensure the quality;

6)Please stir this product evenly before use. Please use up the mixed and mixed materials within 30 minutes. After opening, please close the lid tightly to avoid pollution and water absorption.

7)If there is any objection to the quality of the raw materials, please stop the construction immediately and contact our after-sales service department as soon as possible. If you need to go to the construction site to confirm the quality ownership, our company will send a special person to the site to confirm the cause of the accident (the purchaser, the construction party, producer);

8)Although this product contains a large amount of flame retardants, it is flammable under high temperature and open flames. It must be kept away from open flames during transportation, storage and construction;

9)Although this product is an environmentally friendly product, it is best to operate it under ventilated conditions. Wash your hands after use. If you accidentally get into your eyes, please rinse with plenty of water. If it is serious, please seek medical attention nearby;

10)Good ventilation must be ensured in indoor venues:

11)In the whole construction process, each process should not be soaked in water within 8 hours after construction;

12)After the site is laid, it needs to be maintained for at least 2 days before it can be put into use.